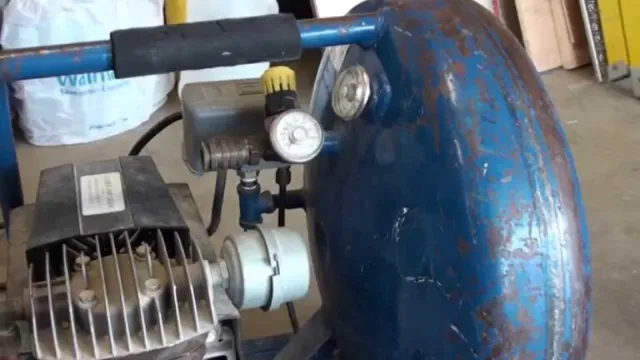

How to Fix a Hole in Air Compressor Tank: Simple DIY Methods

If you own an air compressor, you know how essential it is to maintain it regularly. However, sometimes accidents happen, and your air compressor tank might develop a hole or a crack. It can be frustrating to have a broken compressor tank, and the last thing you want to do is buy a new one.

Fortunately, you can fix the hole in your air compressor tank and get it back up and running in no time! In this blog post, we will show you some steps on how to fix a hole in your air compressor tank, and you’ll be back to using your air compressor like it’s brand new! So, let’s dive right in!

Identify the Size and Location of the Hole

When it comes to fixing a hole in your air compressor tank, the first step is to identify the size and location of the hole. This might sound obvious, but it’s important to get a clear view of what you’re dealing with before you start any repairs. To locate the hole, you can use soapy water and a brush to spray around the tank.

Bubbles will form where the hole is located, making it clear where to start your repairs. As for the size of the hole, this will determine the type of repair you’ll need to make. If the hole is small, you may be able to simply seal it with silicone caulk or epoxy putty.

However, if the hole is bigger, you’ll need to use patches and welding to fix the issue. Remember to stay safe when making any repairs and always follow the manufacturer’s instructions. With the right approach, fixing a hole in your air compressor tank can be a straightforward process.

Check for Leaks

When you suspect a leak in your house, the first thing to do is identify the size and location of the hole. The most common signs of a leak are a sudden increase in your water bill, damp or discolored ceilings or walls, and the sound of running water that can’t be pinpointed to any specific source. Once you’ve noticed these signs, it’s important to act quickly and methodically to identify the location and size of the leak.

Start by turning off all your water sources, then check your water meter to see if it’s still moving. If it is, you likely have a leak. From there, the next step is to systematically check every fixture and appliance in your house for any signs of damage or wear and tear.

Using a flashlight and towel, examine pipes and hoses for any visible cracks or holes, and look for dampness or mold in carpeting or flooring around appliances like washing machines and dishwashers. By taking these steps, you can quickly identify the size and location of a leak and start taking steps to address it before it causes any more damage to your home.

Clean the Area Around the Hole

When it comes to patching a hole in your wall, be sure to take the time to identify the size and location of the hole before starting any repairs. Start by measuring the size of the hole and determining its location in the room, as this will help you properly prepare the area for repair. Once you’ve done this, it’s important to clean the area around the hole thoroughly, removing any debris or loose pieces of drywall.

Doing so will help ensure that the patch sticks and adheres well to the wall, creating a seamless finish. Remember to also use a primer on the patch once it’s in place, as this will help the paint adhere and blend in more easily. With these steps in mind, you’ll be well on your way to repairing any holes in your walls with ease!

Repairing the Hole

If you find yourself with a hole in your air compressor tank, don’t worry, it can be fixed! First, make sure to relieve the pressure from the tank and drain any remaining air and moisture. Next, clean the area around the hole with a wire brush or sandpaper to remove any rust or debris. Once clean, you can use a specialized epoxy or welding technique to seal the hole.

For smaller holes, an epoxy putty can work well, but for larger holes or cracks, it is best to weld a patch over the area. Make sure to carefully follow the instructions for your chosen repair method and allow sufficient time for the product to dry or set before testing the tank’s pressure. With some patience and attention to detail, your air compressor tank can be repaired and ready for use again in no time.

Welding the Hole

If you’re dealing with a hole in your metal structure, welding is one of the best methods to repair it. Welding the hole involves bringing two pieces of metal together by melting them with extreme heat and then fusing them with a metal filler rod. This method can be done on different types of metals, including steel, aluminum, and copper.

When welding a hole, it is important to ensure that the filler rod has the same composition as the metal being welded to maintain strength and durability. By welding the hole, you can restore the structure’s integrity and prevent further damage. Welding should only be performed by a trained professional who is well-versed in the art of welding to ensure safety and effectiveness.

Overall, welding is a reliable and effective method of repairing holes in metal structures.

Using J-B Weld

If you have a hole in your favorite item, don’t worry, it’s not the end of the world. With J-B Weld, you can easily fix it without breaking a sweat. First, clean the area around the hole thoroughly with sandpaper.

Then, mix the J-B Weld solution thoroughly, following the instructions on the package. Once the solution is ready, apply a small amount to the area around the hole, making sure you cover it entirely. After a few hours, the solution should harden, creating a strong and durable bond.

You can even sand it gently to make sure the repair blends in with the surrounding area. J-B Weld is an easy and affordable solution to fix holes, cracks, or other damages in your belongings, making them good as new.

Using a Patch

Using a patch is a great way to repair a hole in your clothing or other fabric items. The first step is to select a patch that is similar in color and material to the item you are repairing. Next, clean the area around the hole to remove any dirt or debris.

Then, apply a small amount of fabric glue around the edge of the hole and place the patch over it. Press firmly to ensure a tight seal and let it dry completely before wearing or washing the item. With a little practice, patching can become a quick and easy solution for repairing small holes in your favorite clothing items.

Remember to always follow the instructions on the fabric glue and patch packaging for best results.

Prevent Future Holes

If you’ve found a hole in your air compressor tank, fixing it is only the first step in preventing future holes. Regular maintenance and inspections are crucial to keeping your tank in good condition. Make sure to drain the tank daily to prevent moisture buildup, which can lead to corrosion and weaken the metal, making it more vulnerable to holes.

Additionally, check the pressure relief valve regularly to ensure it’s working properly and releasing pressure when necessary. Invest in quality air filters to prevent particles from getting into the tank and causing damage. Lastly, avoid overworking your compressor by using it within its rated capacity and allowing it to cool down between uses.

By taking these preventative measures, you can avoid future holes in your air compressor tank and ensure its longevity.

Regular Maintenance

Regular maintenance is crucial if you want to prevent future holes in your household items. Simple tasks such as checking for leaks or cracks in your pipes and filling in any gaps in your windows can help you avoid costly repairs down the line. Just like how a car needs regular oil changes and tune-ups to prevent breakdowns, your home also requires routine maintenance to keep it in optimal condition.

Investing in regular upkeep can ensure that your belongings last longer and saves you from having to replace them frequently. As the old saying goes, prevention is better than cure. Set aside a regular maintenance schedule for your home, and you’ll be able to avoid the need for expensive repairs or replacements later on.

Proper Use

When it comes to proper use of clothing, there are a few things to keep in mind that can help prevent future holes. First, be mindful of the fabric of your clothing and pay attention to any care instructions on the tag. Stretchy or delicate fabrics require a gentler touch than sturdier materials like denim or canvas.

Second, consider your activities when choosing what to wear. If you know you’ll be doing something that may put extra strain on your clothing, such as lifting heavy objects or crawling on the ground, opt for something sturdier or wear protective gear. Lastly, be mindful of any accessories you’re wearing, such as belts or jewelry, that may rub against your clothing and cause damage.

By taking these simple steps, you can help extend the life of your clothing and save money in the long run.

Conclusion

When it comes to fixing a hole in your air compressor tank, the solution is pretty straightforward: patch it up! However, it’s important to choose the right method and materials to ensure a safe and effective repair. Whether you opt for welding, brazing, or epoxy, make sure you follow proper safety precautions and seek professional guidance if needed. And if all else fails, consider embracing the hole as a unique design feature – after all, who says a compressor tank can’t have a little character?”

FAQs

What causes a hole in an air compressor tank?

A hole in an air compressor tank can be caused by rust, corrosion, impact damage, or vibrations.

Can a hole in an air compressor tank be repaired?

Yes, a hole in an air compressor tank can be repaired. However, the repair process can differ depending on the size and location of the hole.

How do I locate the hole in my air compressor tank?

To locate a hole in an air compressor tank, you may need to use soap solution or a leak detector spray to identify any escaping air or bubbles around the area.

Is it safe to continue using an air compressor with a hole in the tank?

No, it is not safe to use an air compressor with a hole in the tank. This can lead to decreased efficiency, increased risk of explosion, and potential injury to the operator.

Can I prevent holes in my air compressor tank?

To prevent holes in your air compressor tank, you can regularly inspect and maintain the tank, avoid exposing it to harsh environments, and ensure that it is adequately supported and installed on a stable surface.

What materials are needed to repair a hole in an air compressor tank?

To repair a hole in an air compressor tank, you may need a welding kit, sheet metal, epoxy, or specialized repair products designed for this purpose.

Do I need to empty the tank before repairing a hole?

Yes, it is necessary to empty the tank before repairing a hole to avoid any hazards associated with combustible air or fuels. It is also essential to properly vent the tank to prevent pressure buildup during the repair process.