What Happens if You Don’t Use a Torque Wrench? The Importance of Proper Bolt Tightening Techniques

Have you ever struggled with over-tightening or under-tightening bolts and screws? If so, you’re not alone. Many DIY enthusiasts and professionals alike face this problem when working on projects that require precise torque measurements. This is where torque wrenches come into play.

They are essential tools for tightening fasteners to a specific torque specification, allowing for accurate and consistent results. In this blog, we’ll explore the importance of torque wrenches, how they work, and why they’re necessary in both industrial and domestic settings. So, grab a cup of coffee, sit back, and let’s dive into the world of torque wrenches.

What is a Torque Wrench?

What is a torque wrench and what happens if you don’t use it? A torque wrench is a specialized tool used to tighten bolts or nuts to a specific torque value. This is particularly important when working with machinery where properly torqued fasteners are essential for safe and reliable operation. If you don’t use a torque wrench and simply rely on your own strength and judgement, you run the risk of either over-tightening or under-tightening bolts, both of which can lead to problems down the road.

Over-tightening can cause bolts to break or strip, while under-tightening can result in fasteners loosening over time and potentially causing equipment failure. By using a torque wrench, you can ensure that fasteners are tightened to the manufacturer’s specifications and you can avoid potential problems caused by improperly torqued bolts. So, always use a torque wrench and save yourself from potential headaches and safety hazards.

Definition and Function of Torque Wrench

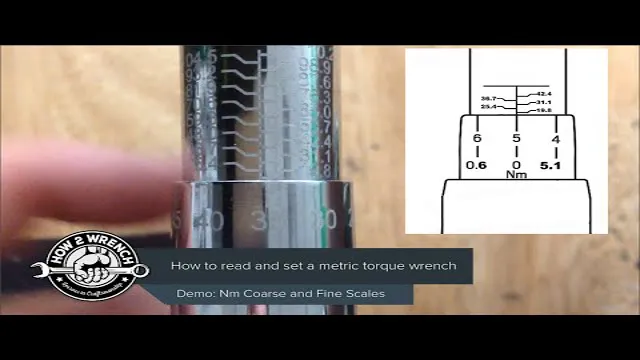

A torque wrench is a tool used to tighten bolts or nuts to a specific torque level. It applies a specific amount of force to the fastener, ensuring that it is tightened to the exact level required for the job. A torque wrench is an essential tool for mechanics and engineers who need to ensure the accuracy and consistency of fastener tightening.

It comes in many sizes and types, including manual, digital, and electronic versions. The torque wrench is a precision instrument that enables you to tighten bolts and nuts to the proper torque specification, reducing the risk of over-tightening or under-tightening. By using a torque wrench, you can ensure that your equipment operates safely and efficiently, preventing damage to valuable machinery and ensuring safety for those working with it.

Whether you are a professional mechanic or a DIY enthusiast, the torque wrench is a crucial tool that should be a part of your toolbox.

Why Use a Torque Wrench?

If you don’t use a torque wrench, you risk damaging your equipment and jeopardizing safety. A torque wrench ensures that bolts are tightened to the manufacturer’s specifications, preventing over-tightening or under-tightening. Over-tightening can lead to threads stripping and parts warping or cracking, while under-tightening can cause parts to loosen and fall off during operation.

Not only can these issues be costly, but they can also pose serious safety risks. Using a torque wrench is a simple and effective way to ensure that your equipment is properly maintained and your workplace is safe for everyone. Don’t let simple oversights lead to expensive repairs or dangerous accidents – use a torque wrench to keep everything in order.

Benefits of Using a Torque Wrench

If you’re wondering why you need to use a torque wrench, the answer is simple: accuracy. A torque wrench is a specialized tool that allows you to tighten bolts and nuts precisely to a specified level of tightness. Inaccurate tightening of bolts and nuts can lead to under-tightening, which may result in parts shifting or coming loose from one another, or over-tightening, which can cause damage or breakage.

A torque wrench ensures that every bolt and nut is tightened with the appropriate level of force, so you can be confident that everything will remain secure. Not only does this ensure your safety, but it also helps avoid unnecessary costs of replacing parts that could have been damaged due to incorrect torque. So if you want to avoid potential hazards and unnecessary costs, investing in a torque wrench is definitely worth considering.

Prevent Overtightening or Undertightening

Using a torque wrench is crucial to prevent overtightening or undertightening of bolts, nuts, and other fasteners. Overtightening can lead to damaged threads, which can cause the fastener to weaken and ultimately fail. On the other hand, undertightening can lead to a loose connection, which can also result in failure.

A torque wrench enables you to achieve the exact amount of force required for a specific application. By using a torque wrench, you can ensure that the fastener is tightened to the manufacturer’s specification, avoiding any potential issues down the line. Investing in a torque wrench is a small price to pay compared to the cost and inconvenience of a failed connection.

Ensure Maximum Performance and Safety

If you’re looking for a way to ensure maximum performance and safety when working with mechanical parts, investing in a torque wrench is a wise decision. Torque wrenches are specifically designed to tighten nuts, bolts, and other fasteners to a specific torque value, which is crucial in preventing over-tightening or under-tightening. This not only ensures maximum efficiency of the part but also reduces the risk of damage or injury caused by broken or loose components.

Using a torque wrench also improves consistency and accuracy, as it eliminates the guesswork that comes with manual tightening. So, if you want to take the guesswork out of your mechanical work and ensure reliable performance and safety, a torque wrench is the way to go. And, with many different options available on the market, you can find one that fits your specific needs and budget.

What Happens If You Don’t Use a Torque Wrench?

Not using a torque wrench can have serious consequences. Without the proper torque, bolts and nuts can loosen or even fall off completely, leading to reduced performance and safety risks. Under-torquing can cause parts to wear prematurely or even break, resulting in costly repairs or complete failure.

Over-torquing can also cause damage, as it can stretch or even break bolts, leading to potential safety hazards. Furthermore, over-torqued parts may become difficult to disassemble, making future maintenance a challenge. Ultimately, using a torque wrench is the best way to ensure proper torque and prevent potential issues down the line.

So, don’t skimp on this important tool and adhere to proper torque specifications to keep things running smoothly and safely.

Under- or Over-Tightening the Bolts

If you don’t use a torque wrench when tightening bolts, you run the risk of under- or over-tightening them. Under-tightening can lead to the bolts coming loose over time, which can cause all sorts of problems depending on what the bolts were securing. On the other hand, over-tightening can lead to the bolt breaking or damaging the components it was securing.

It’s important to use a torque wrench to ensure that the bolts are tightened to the proper specifications. Think of it like trying to thread a needle without glasses – you might get lucky and get it right, but more often than not, you’re going to miss the mark. Using a torque wrench takes the guesswork out of the equation and ensures that your bolts are tightened to just the right amount.

It’s a small investment that can save you a lot of headaches down the road.

Damage to the Bolts, Nuts, and Other Parts

If you don’t use a torque wrench, you risk causing damage to the bolts, nuts, and other parts of your machinery. When tightening bolts manually, it is easy to overtighten or undertighten them, which can lead to an array of problems. For instance, overtightening can stretch bolts beyond their yield point, causing them to lose their clamping force.

On the other hand, undertightening can cause bolts to come loose over time, leading to leaks, wear, and tear. Moreover, when you don’t use a torque wrench, you may not have uniformity in the applied force, which can cause uneven clamping results. Ultimately, uneven clamping force can cause parts to wear more quickly than usual, leading to costly repairs and unplanned downtime.

In summary, if you want to avoid such problems, invest in a torque wrench to ensure uniformity in your applied force. Using a torque wrench guarantees that each bolt is tightened to the correct specification’s torque value, reducing the risk of damage to your machinery.

Safety Risks and Performance Issues

Using a torque wrench is crucial for ensuring safety and performance when working with fasteners. If you don’t use a torque wrench, you may run the risk of over-tightening or under-tightening your nuts and bolts. Over-tightening can lead to thread damage, bolt breakage, and even safety hazards, whereas under-tightening can cause loosening, poor performance, and failure of the fastener system.

Without a torque wrench, it’s nearly impossible to achieve accurate and consistent torque levels, which can lead to serious consequences. Think of it like driving a car without a speedometer. You may think you’re going the speed limit, but without a gauge, you can’t be sure.

A torque wrench is like that speedometer, giving you precise control and accuracy when tightening fasteners for optimal safety and performance. So, always make sure to use a torque wrench to avoid any unwanted risks, both for your safety and the safety of those around you.

Conclusion

If you don’t use a torque wrench, it’s like playing a game of Jenga without following any rules. Sure, you might get lucky and the tower won’t crumble, but more often than not, it’s gonna come crashing down. So, if you want to avoid being the cause of a catastrophic failure, why not tighten things up and use a torque wrench? Your hardware, and the people who rely on it, will thank you.

“

Benefits of Using a Torque Wrench vs Not Using One

Torque Wrench When it comes to tightening bolts and nuts, using a torque wrench is essential. Not using a torque wrench can result in over or under-tightened fasteners, leading to a host of problems. Over-tightening bolts can cause the fastener to stretch or even break, leading to safety hazards.

On the other hand, under-tightening bolts can cause them to come loose, leading to a lack of structural integrity. This is where a torque wrench comes in handy. It ensures that fasteners are tightened to the right specification, preventing any dangerous scenarios.

So, don’t risk damaging your equipment or causing injury, invest in a torque wrench today and ensure your fasteners are tightened to the right specs every time.

FAQs

What is a torque wrench and how does it work?

A torque wrench is a tool used to tighten bolts or nuts to a specific amount of torque. It works by measuring the amount of force applied to the fastener.

Can you tighten bolts without a torque wrench?

Yes, you can tighten bolts without a torque wrench, but it’s not recommended. Tightening bolts without a torque wrench can lead to uneven bolt tension, which can cause the bolt to break or come loose over time.

What happens if you over-tighten a bolt?

Over-tightening a bolt can cause the bolt to snap, strip the threads of the bolt, or damage the threaded hole in the material being fastened.

What happens if you under-tighten a bolt?

Under-tightening a bolt can cause it to come loose over time, which can lead to a failure of the material being fastened. This can be dangerous in situations like automotive or airplane maintenance.

Do all bolts and nuts require a torque wrench?

Not all bolts and nuts require a torque wrench. However, some applications may require precise torque settings to ensure proper and safe fastening.

Can you use a regular wrench instead of a torque wrench?

You can use a regular wrench to tighten bolts, but it will not provide the same level of precision as a torque wrench. The risk of over or under-tightening the bolt will be higher.

How often should you calibrate your torque wrench?

It is recommended to calibrate your torque wrench every year or after every 5,000 cycles of use, whichever comes first. Calibrating helps ensure the tool is providing accurate measurements, which is crucial for safe and effective fastening.