What is the Function of a Torque Wrench and How to Properly Use it for Precise Bolt Tightening?

Are you familiar with torque wrenches and how to use them properly? If you’re a DIY enthusiast or a mechanic, understanding torque wrenches is crucial. A torque wrench is a tool that applies a specific amount of force or torque to a bolt or nut. This tool can help prevent over-tightening or under-tightening, which can lead to damage or safety hazards.

Different torque wrenches are designed for different needs, so choosing the right one can make all the difference in your project’s success. In this blog, we’ll discuss the fundamentals of torque wrenches and how to use them effectively. By the end of this article, you’ll have a better understanding of how to use torque wrenches like a pro!

What is a torque wrench?

A torque wrench is a tool used to measure and apply a specific amount of torque or rotational force to a fastener like a bolt or a nut. The function of a torque wrench is to ensure that fasteners are tightened to a precise level of tension for safety and accuracy. If a fastener is over-tightened, it can damage the bolt or the surrounding material, while an under-tightened fastener can lead to loose connections and structural weaknesses.

A torque wrench measures the amount of force applied and lets the user know when they have reached the desired torque level. There are different types of torque wrenches, including mechanical, digital, and hydraulic, each suited for various applications. A torque wrench is an essential tool in several industries, including automotive, aviation, and construction, helping to improve quality control, prevent accidents, and save time and money.

Therefore, it is necessary to use a torque wrench for appropriate torque on bolts and nuts, making a connection secure and safe.

Definition and purpose

A torque wrench is a tool used specifically for tightening bolts and nuts to a desired torque value. It works by applying force to the nut or bolt, rotating it until the desired torque value is achieved. There are various types of torque wrenches, including beam, click, digital, and dial.

In general, they all serve the same purpose – ensuring that bolts are tightened to the manufacturer’s recommended torque specifications. The purpose of a torque wrench is to ensure that the fastener is not too loose, which could lead to failure, or too tight, which could damage the equipment. It is especially crucial in industries where safety is a top priority, such as the automotive industry or in construction.

A torque wrench is often used by mechanics, technicians, and engineers who work with heavy machinery or critical components. By using a torque wrench, one can guarantee that bolts are tightened correctly and safely.

Types of torque wrenches

A torque wrench is a tool used to tighten nuts or bolts to a specific level of torque. It is essential in many industries where tightening of fasteners is necessary, and over or under-tightening can lead to severe complications. There are several types of torque wrenches available in the market.

Click-type torque wrenches are the most common ones, and they make a clicking sound when the desired torque level is reached. Beam-type torque wrenches measure torque by the deflection of a beam under load. Dial-type torque wrenches display the torque measurement on a dial indicator, which makes them the easiest to read.

Digital torque wrenches use an electronic sensor to determine the torque measurement, and they usually have a digital display. These types of wrenches come in different shapes and sizes, such as the breaker bar torque wrench, which is designed to remove stubborn nuts and bolts. Overall, the type of torque wrench you choose will depend on your specific needs and preferences.

Regardless of the type, a torque wrench is a valuable tool for any person or industry that requires precise and accurate torquing of fasteners.

How does a torque wrench work?

A torque wrench is a tool used to tighten nuts and bolts to a specific level of tightness. The function of a torque wrench is to apply the exact amount of force required to tighten the fastener without over-tightening or under-tightening, which is crucial for safety and proper functioning of the machinery. When the wrench is applied, it generates a twisting force or torque around the bolt, which is measured by a scale or gauge on the wrench.

Once the desired level of torque is reached, the wrench will either click, vibrate, or display a visual indication, indicating the nut or bolt is correctly tightened. Different types of torque wrenches are available for various applications, such as digital or dial torque wrenches, beam-style torque wrenches, and electronic torque wrenches. By utilizing a torque wrench, you can ensure that your fasteners are tightened to the precise specifications, thus preventing damage, wear and tear, and potential accidents from occurring.

Mechanism and operation

A torque wrench is a tool designed to tighten nuts and bolts to a precise level of torque. It works on the principle of applying a specific amount of force or torque to the fastener. The mechanism of the torque wrench involves a spring-loaded wrench, which is attached to a calibrated metal rod.

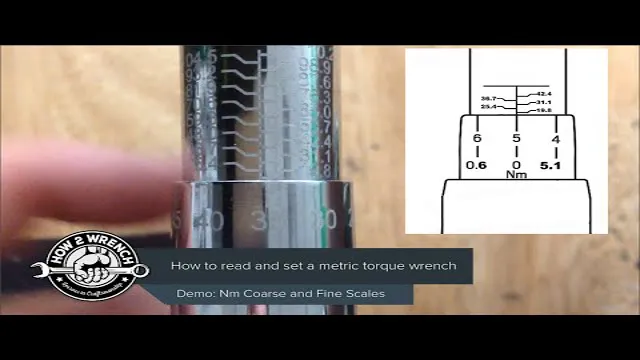

When the wrench is rotated, the rod compresses the spring, and the force exerted on the fastener is measured using a gauge located at the end of the wrench. The gauge displays the amount of force applied in units of torque, usually expressed in foot-pounds or Newton-meters. The operator of the torque wrench can adjust the torque setting using a knob located near the handle, which moves the calibrated metal rod on the spring.

Once the desired torque level is reached, the wrench produces a click sound, indicating that the fastener is securely tightened to the required level. Using a torque wrench ensures that fasteners are adequately tightened, preventing under or over-tightening, and reducing the risk of damage or failure. So, it’s a handy tool for DIY and professional mechanics alike.

Accuracy and precision

When it comes to accurate and precise tightening of bolts or nuts, a torque wrench is an essential tool for any DIY enthusiast or professional mechanic. But how does it work? Simply put, a torque wrench measures the amount of force being applied to a bolt or nut and alerts the user when the desired torque has been reached. This is achieved through a mechanical or electronic device that measures the amount of applied force and converts it into a torque value.

The user sets the desired torque on the wrench and tightens the bolt or nut until the wrench clicks or displays the desired torque. The main keyword, torque wrench, plays a critical role in ensuring that bolts and nuts are tightened to the manufacturer’s recommendations and prevent overtightening, which can lead to damage to the component being fastened.

Why use a torque wrench?

Are you wondering what the function of a torque wrench is and why it’s important to use one? Well, a torque wrench is a tool designed to help tighten bolts and nuts to a specific level of tightness. This level of tightness, also known as torque, is crucial in ensuring that the fastener is secure enough to hold the load or tension it’s meant to handle. Without the proper torque, bolts can become loose, leading to damage, safety hazards, and even failure.

A torque wrench helps prevent these issues by providing precise torque readings, allowing you to tighten bolts and nuts to the manufacturer’s specifications. Using a torque wrench can also extend the lifespan of your equipment or machinery, as over-tightening or under-tightening of bolts can cause unnecessary wear and tear. So, the next time you need to tighten bolts or nuts, make sure to use a torque wrench to ensure the best possible outcome.

Benefits of using a torque wrench

If you’re someone who often works with fasteners or machinery, you know how important it is to tighten bolts and nuts correctly. This is where a torque wrench comes in handy, as it provides you with the precise amount of force needed for the particular task at hand. The benefits of using a torque wrench are numerous, including the assurance that your work is safe, accurate, and consistent.

For instance, when you tighten a bolt without a torque wrench, you may overtighten or undertighten it, leading to potential damage and safety issues. However, when you use a torque wrench, you ensure that each nut or bolt gets tightened precisely to the manufacturer’s recommended torque specifications, eliminating the guesswork. Furthermore, a torque wrench can also prevent overtightening, which can lead to stripped threads, damaged parts, or even sheared bolts.

Overall, using a torque wrench is a wise investment that can help you save time, money, and increase safety on the job.

Applications and industries

If you’re working with machinery that requires bolts, nuts, or screws, it’s essential to use the right amount of torque to ensure that everything stays put and doesn’t come loose over time. That’s where a torque wrench comes in. This handy tool ensures that you are applying the correct level of force to tighten fasteners to the manufacturer’s recommendations, preventing failures and mishaps.

It is especially important in industries like automotive, aerospace, construction, and manufacturing, where precision and accuracy are paramount. Using a torque wrench can also help you achieve optimal results when working on smaller-scale projects, such as assembling furniture or repairing appliances. So, whether you’re a professional mechanic or a DIY enthusiast, a torque wrench is a must-have tool in your arsenal to ensure that everything is safe, secure, and perfectly tightened.

Using a torque wrench safely

A torque wrench is a tool used to accurately tighten bolts and nuts to a specific torque value. But what is the function of a torque wrench? Well, the torque wrench is designed to measure the amount of force applied to the fastener, ensuring that it is not overtightened or undertightened. This is critical because over-tightening can cause damage to the parts being joined, while under-tightening can result in a loose, unstable connection.

As such, the torque wrench is an essential tool for mechanics, engineers, and DIY enthusiasts alike. When using a torque wrench, it’s important to follow the manufacturer’s instructions and set the tool to the correct torque value. Failure to do so could result in damaged parts, injury, or even death.

By using a torque wrench safely and correctly, you can ensure that your projects are completed to the highest standards, and with the utmost safety.

Tips and guidelines

If you’re planning to do some mechanical work on your vehicle or machinery, properly torquing bolts and fasteners is essential to ensure safety and proper operation. A torque wrench is a valuable tool to accomplish this task, but it’s important to use it safely and accurately. Firstly, always consult the manufacturer’s specifications to determine the correct torque settings for your project.

Secondly, make sure the torque wrench is set correctly before use and double-check if necessary. Never use a torque wrench to loosen bolts or use it as a breaker bar. Lastly, store your torque wrench safely to prevent accidental damage or misuse.

Following these simple tips and guidelines will not only protect your equipment and finished project, but it’ll also keep you safe in the process.

Precautions and warnings

If you’re planning to use a torque wrench, it’s essential to take necessary precautions to ensure your safety. Proper usage of torque wrenches requires a basic understanding of their functionality and application. Before using a torque wrench, it is important to verify the correct torque value for the fastener that needs to be fastened.

Once you set the torque wrench accordingly, ensure that the fastener is secured correctly and that you are using the correct socket size. While applying force using the wrench, be cautious of any torque specifications that require additional accuracy or precision. You should also avoid using a torque wrench that is damaged or worn out, as it could lead to ineffective results or cause an accident.

Always keep in mind the recommended torque specifications outlined in the manufacturer’s manual. Additionally, maintaining proper posture while using a torque wrench can help prevent musculoskeletal disorders. Remember to take frequent breaks, stretch your muscles, and avoid using excessive force.

With these precautions in mind, using a torque wrench will be a safe and effective tool for all your fastening needs.

Conclusion

So there you have it – the humble torque wrench, a tool designed to literally tighten things up. Whether you’re a mechanic, engineer, or just a regular DIY enthusiast, a torque wrench is an essential piece of equipment for ensuring that bolts, screws, and other fasteners are tightened to the exact specifications required. Not only does this help to prevent damage to machinery and equipment, but it can also help to ensure safety by reducing the risk of bolts coming loose.

So, in short, the function of a torque wrench is to keep things tight and secure – just like your grip on that wrench when you’re powering through a tough job!”

FAQs

What is a torque wrench and how does it work?

A torque wrench is a tool used to apply a specific amount of torque to a fastener. It works by measuring the amount of force being applied and alerting the user when the desired torque has been reached.

How do I choose the right torque wrench for my application?

To choose the right torque wrench, you need to consider factors such as the maximum torque required for the application, the type of fasteners being used, and the accuracy required. You also need to choose between a mechanical or digital torque wrench.

How often should I calibrate my torque wrench?

Torque wrenches should be calibrated before first use, and then at least once a year or after 5,000 cycles, whichever comes first. For critical applications, they may need to be calibrated more frequently.

Can a torque wrench be used for loosening bolts or just tightening them?

In general, torque wrenches are designed for tightening bolts, not loosening them. Attempting to use a torque wrench to loosen bolts could damage the tool and compromise its accuracy.

What are the benefits of using a torque wrench?

Using a torque wrench ensures that fasteners are tightened to the correct torque, which helps prevent damage or failure due to over- or under-tightening. This can improve safety, increase the lifespan of equipment, and reduce the risk of warranty claims.

Can a torque wrench be used on all types of fasteners?

Torque wrenches are designed to work with specific types of fasteners, such as bolts and nuts. They may not be suitable for use with other types of fasteners, such as screws or rivets.

What is the difference between a click-type and beam-type torque wrench?

Click-type torque wrenches emit a clicking sound when the desired torque has been reached, while beam-type torque wrenches use a visual indicator to show when the correct torque has been achieved. Click-type torque wrenches are generally more popular due to their ease of use and accuracy.