Which Torque Wrench Do I Need for My Car? A Comprehensive Guide

If you’re someone who likes to work on cars or heavy machinery, you know the importance of having the right tools for the job. One such tool that can make a significant difference is a torque wrench. However, with so many types of torque wrenches available in the market, it can be challenging to determine which one is right for you.

It’s essential to understand that different scenarios require different types of wrenches. For instance, if you work on cars, you’ll need a different torque wrench than someone who works on heavy machinery. Additionally, the amount of torque required also varies, meaning that the torque wrench you need for one job might not work for another.

But don’t worry, we’re here to help. In this blog, we’ll go over the various types of torque wrenches available, the scenarios they’re best suited for, and how to know which one you need. So, whether you’re a beginner or a seasoned mechanic, read on to find out which torque wrench is the right fit for you.

Understanding Torque Wrenches

If you’re wondering which torque wrench to buy, it all depends on what you’re using it for. Torque wrenches come in many different shapes and sizes, each with their own specific uses. If you’re working on a car or truck, you’ll likely need a larger torque wrench that can handle higher torque values.

On the other hand, if you’re working on smaller, precision tasks, such as on a bicycle or motorcycle, a smaller torque wrench may be more appropriate. It’s important to consider the range of torque values you’ll need to work with, as well as the type of drive mechanism on the wrench itself. Some wrenches use a square drive, while others use a hex drive, which can affect the types of sockets you’ll need to use.

Ultimately, it’s important to do some research and find a torque wrench that fits your needs, whether that’s a digital or analog version, a beam, click, or dial type wrench, or a specific brand or model.

What is a Torque Wrench?

Torque wrench Torque wrenches are specialized tools used to tighten bolts to a specific torque setting. This is important because over-tightening can lead to damage, while under-tightening can result in the bolt loosening or failing completely. Torque wrenches come in a variety of types, including beam, click, and digital models.

The beam type is the simplest and typically the most affordable, while the click and digital types are more precise and provide visual or audible feedback when the correct torque setting is reached. Understanding how to use a torque wrench is essential to ensuring proper bolt tightening for a variety of applications, from automotive repair to construction. By using a torque wrench, you can have confidence that your bolts are tightened to the correct specification, helping to prevent costly damage and ensuring safety.

Why do you need a Torque Wrench?

If you’re wondering why you need a torque wrench, the answer is simple: it ensures precise and accurate tightening of bolts and nuts. Sounds simple enough, but when you’re working on something with delicate components, such as an engine or a bicycle, overtightening or undertightening could lead to disastrous consequences. That’s where a torque wrench come in handy.

It allows you to tighten bolts and nuts with a specific amount of force, ensuring that they are precisely tightened to the manufacturer’s specifications. This is especially important when working with high-stress components like suspension parts, brake calipers, and cylinder heads. A torque wrench also helps prevent under or over-tightened bolts that can cause damage to your equipment.

Think of it as a “measuring tape” for the amount of force needed to tighten a bolt or nut, giving you peace of mind and ensuring proper functionality. Choosing the right torque wrench depends on the job you’re doing, but there are many options available to meet your specific needs. So, next time you’re working on something that requires precise tightening, consider adding a torque wrench to your toolkit.

Factors to Consider Before Buying a Torque Wrench

If you’re in the market for a torque wrench, there are a few important factors to consider before making your purchase. First and foremost, you’ll want to determine what type of work you’ll be using the wrench for. Different wrenches are designed for different applications, so it’s important to choose one that is appropriate for the tasks at hand.

You’ll also want to consider the torque range of the wrench, as well as its accuracy and ease of use. Other factors to consider include the size and weight of the wrench, as well as its overall durability and reliability. With so many options available, it can be difficult to choose the right torque wrench for your needs, but by taking the time to carefully consider these factors, you can ensure that you end up with a tool that is reliable, accurate, and easy to use.

So, which torque wrench do you need? The answer depends on your specific needs and the types of tasks you’ll be tackling, but by doing your research and carefully considering your options, you can find the right tool for the job.

Torque Range

When looking for a torque wrench, the range of torque it can handle is a crucial factor to consider. The torque range defines the maximum and minimum amount of force the wrench can apply to a bolt or nut. It’s essential to select a torque wrench that can accommodate the specific requirements of your tasks.

Choosing an inadequate tool can lead to under or over-tightening, causing significant damages or even accidents. It’s advisable to assess the torque range of your potential wrench options and determine if they match your needs. Don’t go for a wrench with an excessively broad range that can compromise its accuracy and effectiveness.

Instead, select a tool with a moderate range that suits your typical applications. Remember, the torque range differs amongst brands and models, so make sure you compare different options to make an informed choice. By assessing the torque range, you’re sure to choose a reliable and durable torque wrench that will get the job done efficiently.

Accuracy

When it comes to buying a torque wrench, accuracy is one of the most important factors to consider. Why? Because an inaccurate torque wrench can compromise the safety and performance of your vehicle or equipment. In order to ensure accuracy, you should look for a torque wrench that has a high level of precision and is calibrated regularly.

It’s also important to choose a torque wrench that is appropriate for the task at hand. For example, a small torque wrench may not be accurate enough for larger bolts or applications. Additionally, you should consider the quality of the materials used in the torque wrench, as well as the reputation of the manufacturer.

By taking these factors into account, you can find a torque wrench that will provide reliable and accurate results, every time.

Durability and Quality

When it comes to buying a torque wrench, one of the most important factors to consider is durability and quality. You want a tool that can withstand frequent use without breaking down or losing accuracy. Look for wrenches made from high-quality materials such as chrome vanadium or alloy steel, as these materials are known for their strength and durability.

Additionally, pay attention to the overall construction of the wrench, ensuring that it has a sturdy design and is well-made. A reliable torque wrench will not only save you money in the long run but also provide you with the confidence to tackle any job knowing that you have a tool you can trust. So, before making a purchase, be sure to do your research and choose a torque wrench that will stand the test of time and deliver accurate results each time you use it.

Ease of Use and Comfort

When it comes to purchasing a torque wrench, there are several factors to consider before making your final decision. One of the most important factors is ease of use and comfort. You want to choose a torque wrench that is easy to operate and doesn’t require a lot of effort to use.

Additionally, you want to make sure that the wrench feels comfortable in your hand. A torque wrench that is too heavy or bulky can make it difficult to use, which can lead to inaccuracies or even injury. When shopping for a torque wrench, make sure to look for one that is user-friendly and ergonomically designed to optimize your experience.

Don’t forget to read reviews and get recommendations from other users to ensure that you’re making the best choice for your needs.

Types of Torque Wrenches

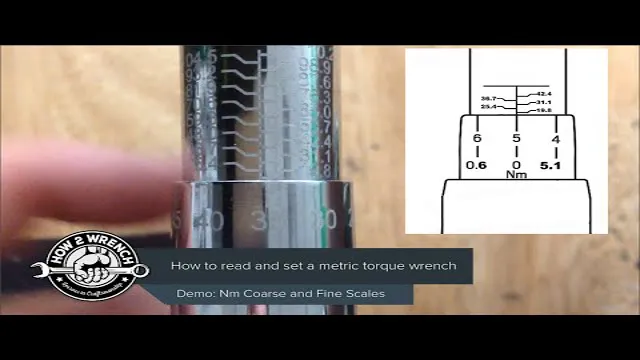

If you’re wondering which torque wrench you need, it’s important to know that there are several types to choose from. The most common types of torque wrenches are beam, click, and digital. A beam torque wrench is the most basic type, and it works by using a simple lever arm to apply torque.

A click torque wrench, on the other hand, uses a clutch mechanism that makes an audible click when the desired torque level is reached. Digital torque wrenches use electronic sensors to provide precise readings, and they often have additional features like storing multiple torque settings or unit conversions. The type of torque wrench you need depends on your specific needs.

If you only need to apply a general torque, a beam torque wrench might be sufficient. However, if you need to apply precise torque levels, a click or digital torque wrench would be more appropriate. It’s also important to consider the torque range you need, as torque wrenches can come in a variety of ranges.

Ultimately, choosing the right torque wrench depends on your specific needs and the type of work you’ll be doing.

Beam Torque Wrench

A beam torque wrench is a popular tool among professionals and DIY enthusiasts alike. It’s a type of torque wrench that uses a long beam to measure torque instead of a mechanical gauge or digital display. Beam torque wrenches are reliable and durable, and they’re ideal for applications where accuracy is vital.

They’re also incredibly easy to use, making them an excellent choice for those who are new to using torque wrenches. There are different types of torque wrenches, and each has its unique features and benefits. For example, the click-type torque wrench emits a clicking sound when the desired torque setting has been reached, while the digital torque wrench displays the measurements on a digital screen.

No matter which type of torque wrench you choose, be sure to use it properly and regularly calibrate it to ensure accurate results every time.

Click Torque Wrench

If you’re going to be working on machinery or other equipment that requires precise tightening of bolts or nuts, you’ll need a torque wrench. There are several different types of torque wrenches available, each with its own strengths and weaknesses. One of the most popular types of torque wrenches is the click torque wrench.

As the name suggests, these wrenches “click” when the desired torque level is reached, letting you know when to stop tightening the bolt. Click torque wrenches are often relatively inexpensive, and they’re typically easy to use – even for people who are relatively new to working with tools. However, they do have some limitations.

For example, they don’t work well in situations where you need to apply a lot of torque, and they can be more difficult to use in tight spaces. Overall, though, click torque wrenches are a great option for many people, especially those who are just starting out with wrenches or who don’t need to do a lot of heavy-duty work.

Dial Torque Wrench

If you need to tighten bolts or nuts to a specific torque setting, then a Torque Wrench is what you need. There are different types of Torque Wrenches, and one of the most popular types is the Dial Torque Wrench. This type of wrench has a dial gauge that shows the torque being applied, which makes it easy to read and monitor.

The Dial Torque Wrench is also known as a Beam Type Torque Wrench, and it is accurate to within 3-5% of the desired torque. This type of wrench is perfect for automotive work, industrial applications, and any other situation where precise torque is required. The Dial Torque Wrench comes in different sizes, ranging from small to large, which makes it easy to use in tight spaces as well as on larger bolts or nuts.

Overall, if you need a reliable, accurate, and easy-to-use Torque Wrench, then the Dial Torque Wrench is a great option to consider.

Electronic Torque Wrench

When it comes to torque wrenches, there are several different types to choose from. One of the most popular options among professionals is the electronic torque wrench. This type of wrench uses electronic sensors to measure the amount of torque being applied to a bolt or nut.

This helps to ensure that the correct amount of force is used, which is extremely important for preventing under- or over-tightening. One of the benefits of electronic torque wrenches is that they usually have digital displays that make it easy to read the torque measurement. Additionally, they often have features like automatic shut-off and programmable presets, making them both convenient and precise.

If you’re in the market for a torque wrench, it’s worth considering an electronic option for all your mechanical needs.

Conclusion

Deciding which torque wrench to use can seem like an overwhelming task, but fear not! With a little bit of knowledge and guidance, you can become a torque-wrench-wielding warrior ready to take on any task. The key is to consider the type of work you’ll be doing and the level of precision required. Whether you’re a professional mechanic or a DIY enthusiast, there’s a torque wrench out there that’s perfect for you.

So, don’t let the endless options torque you off, find the perfect wrench and tighten up those bolts with confidence!”

FAQs

What are the different types of torque wrenches available in the market?

The commonly available torque wrenches are click, beam, dial, and digital torque wrenches.

What type of torque wrench is suitable for automotive work?

Click torque wrenches are the most commonly used torque wrenches for automotive work.

How do I know what torque range I need for my specific application?

Consult the manufacturer’s specifications or reach out to a professional in the industry to determine the appropriate torque range needed.

Can I use a torque wrench for non-automotive purposes?

Yes, torque wrenches can be used for a variety of applications that require precise torque measurements.

How often should I calibrate my torque wrench?

Torque wrenches should be calibrated regularly, ideally every 12 months or after 5,000 uses.

Can I use a digital torque wrench for heavy-duty applications?

Yes, digital torque wrenches can be used for heavy-duty applications, but it is important to ensure the torque range and accuracy meet the requirements of the specific job.

What is the difference between a click and a beam torque wrench?

Click torque wrenches have a clicking sound when the desired torque is reached, while beam torque wrenches have a visible beam that indicates when the desired torque is reached.